Foaming Equipment

No matter the size of your operation Euro Pumps has foaming equipment that’s suitable for your plant

- Quick Release Foaming Tools for hi or low pressure

- Single, and duel chemical injectors

- Central Plant Cleaning System

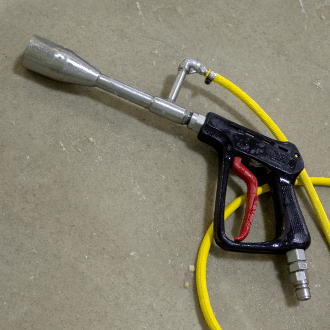

Quick Release Foaming Tools

With the click of a fitting, you can add a Euro Pumps quick release foaming tool to suit a high and low pressure system.

Mobile cleaning and foaming station

German designed mobile cleaning and foaming station for applications in the food industry. Pre-drilled fixing holes for quick mounting of ST-164, ST-167, ST-168 injectors, and/or wall mount hose reels.

-

- Stainless steel construction

- Room for 2 x 25lt chemical Bottles

- Supplied with pre-drilled fixing holes for accesssory installation

- Twin lance holder

- Manoeuvrable and easy to handle

- Ergonomic plastic handle strip which is

easily removable for use in food production - Grey non-fading wheels

- Size 1,150mmH x 540mmW x 620mmD

Foam Injectors

Euro Pumps has a range of single , and duel chemical injectors, these can be fixed or adjustable chemical mix ratio with versions that are switchable for single or multi chemical injectors which are typically for separating foaming and sanitising.

These injectors are designed for low-medium pressure (inlet pressure of 5 bar) generating a perfect foam. The injectors are available in nozzle sizes from 1.2 – 2.8 mm to adjust the chemical mix.

Central Foaming Systems

More companies in the food industry are looking to move towards centralised foaming systems for both the increase in employee safety and regulated chemical usage. The system both eliminates the risk of staff mixing chemical by hand and enhances the accuracy of the mixing. Hence, the boost in worker wellbeing and money saved in wasted chemical make a central foaming system a viable option a lot of companies are leaning towards.

- Drop points can be configured with rinse, foam and/or sanitize functions.

- Central Foam Systems are a safe and cost-effective

- Ideal for distributing a pre-set foaming solution to cleaners

Ask us about ProMinent Chemical Dosing Pumps, metering pumps, positive displacement pumps, and Chemical Dosing Pumps from a variety of capacities, from a few ml to 40,000 l/h.

Foaming and Chemical Pressure Spray Bottles

R+M Suttner Industral line sprayers are specialy designed for extraordinary difficult applications such as Food production, car wash, oil platforms or industrial cleaning applications. They are resistant to lots of chemicals which are used in industry. Due to the acid-resistant lance, the EPDM / Viton seals and the extremely durable high-pressure container the devices are designed for the most difficult cleaning applications. Safety for the user is absolutely guaranteed.

0.5 liters EPDM

Prod No. 106995005

Volume: 0.5 l

Weight: 0.10 kg

Sealing: EPDM

1 liters EPDM

Prod No. 106995010

Volume: 1 l

Weight: 0.10 kg

Sealing: EPDM

1.5 liters EPDM

Prod No. 1069950151

Volume: 1.5 l

Weight: 0.54 kg

Sealing: EPDM

2 liter VITON

Prod No. 1069950202

Volume: 2 l

Weight: 0.65 kg

Sealing: Viton

7 liter EPDM

Prod No. 106995070

Volume: 7 l

Seal kit: EPDM

Height: 470 mm

Diameter: 220 mm

Weight: 2.0 kg

7 liters VITON

Prod No. 1069950701

Volume: 7 l

Seal kit: EPDM

Height: 470 mm

Diameter: 220 mm

Weight: 2.0 kg

9 liters EPDM

Prod No. 106995090

Volume: 9 l

Seal kit: EPDM

Height: 570 mm

Diameter: 220 mm

Weight: 2.2 kg

9 liters VITON

Prod No. 1069950901

Volume: 9 l

Seal kit: EPDM

Height: 570 mm

Diameter: 220 mm

Weight: 2.2 kg

12lt EPDM

Prod No. 106995120

Volume: 12 l

Seal kit: EPDM

Height: 600 mm

Diameter: 220 mm

Weight: 2.4 kg

12lt VITON

Prod No. 106995312

Backpack

Volume: 12 l

Size: 610Hx400Wx150D mm

Weight: 3.6 kg

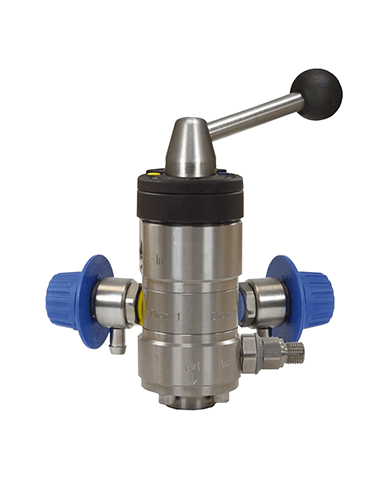

Chemical Injectors

Foaming Injectors device is a combination made out of stainless steel and special high performance plastics. The addition of one out of two connected chemicals is determined by positioning the lever. All versions are suitable for the addition in low pressure from approx. 3 bar up to max. 350 bar.

When being operated in rinsing function up to 60 I/min pass through the unit without any drop in pressure. In combination with a foam lance (ST-72, ST-74 or ST-75), an adjustable or a triple nozzle the ST-164 injector can suck in chemicals by means of the integrated check valve made out of stainless steel and spray them on or foam them depending on the chosen nozzle. The injector has an optional compressed air connection in order to supply the required air quantity for foaming already in the injector unit.

For the application of foam a foam lance without air intake is absolutely required. The use of a spray gun with large cross section areas such as for example ST-2720, ST-2725, ST-3100 or ST-3300 with suitable lances and foam hoses (blufood) is recommended.

The injector is especially designed for low and medium pressure applications from a water inlet pressure of 3 bar and it generates an excellent foam when being provided with the required quantity of compressed air.

The ST-164 injector is available in the nozzle size of 1.2 – 2.8 mm. The dosing is adjusted by one of the 8 nozzle inserts which are included in the consignment. The connection for chemicals is equipped with an integrated check valve.

ST-164 Injector

NO Compressed Air

Input: 3/8″ F

Input: 1/2 ” F

Pressure: . 350 bar Max

Temp: 100 °C

2 x hose tail 9 mm.

The chemical dosing is adjusted by 2 x 8 exchangeable nozzle inserts (0.5 -1.5 mm).

ST-164 Injector+Air

Use With Compressed Air

Input: 3/8″ F

Input: 1/2 ” F

Pressure: . 350 bar Max

Temp: 100 °C

2 x hose tail 9 mm.

The chemical dosing is adjusted by 2 x 8 exchangeable nozzle inserts (0.5 -1.5 mm).

ST-2750 Spray Gun

Available in Nozzle sizes of 1.3mm, 1.4mm, 1.5mm, 1.6mm, 1.7mm, 1.8mm, 1.9mm, 2.0mm, 2.1mm, 2.2mm, 2.3mm, 2.4mm, 2.5mm, and 2.8mm

easyfoam365+

Wall Mount

Wall mount bracket for injectors for ST-164, ST-167, ST-168, ST-160.2, ST-160.3, ST-162