Control Panel Manufacture & System Programming

Euro Pumps design and manufacture industrial control panels and automation systems.

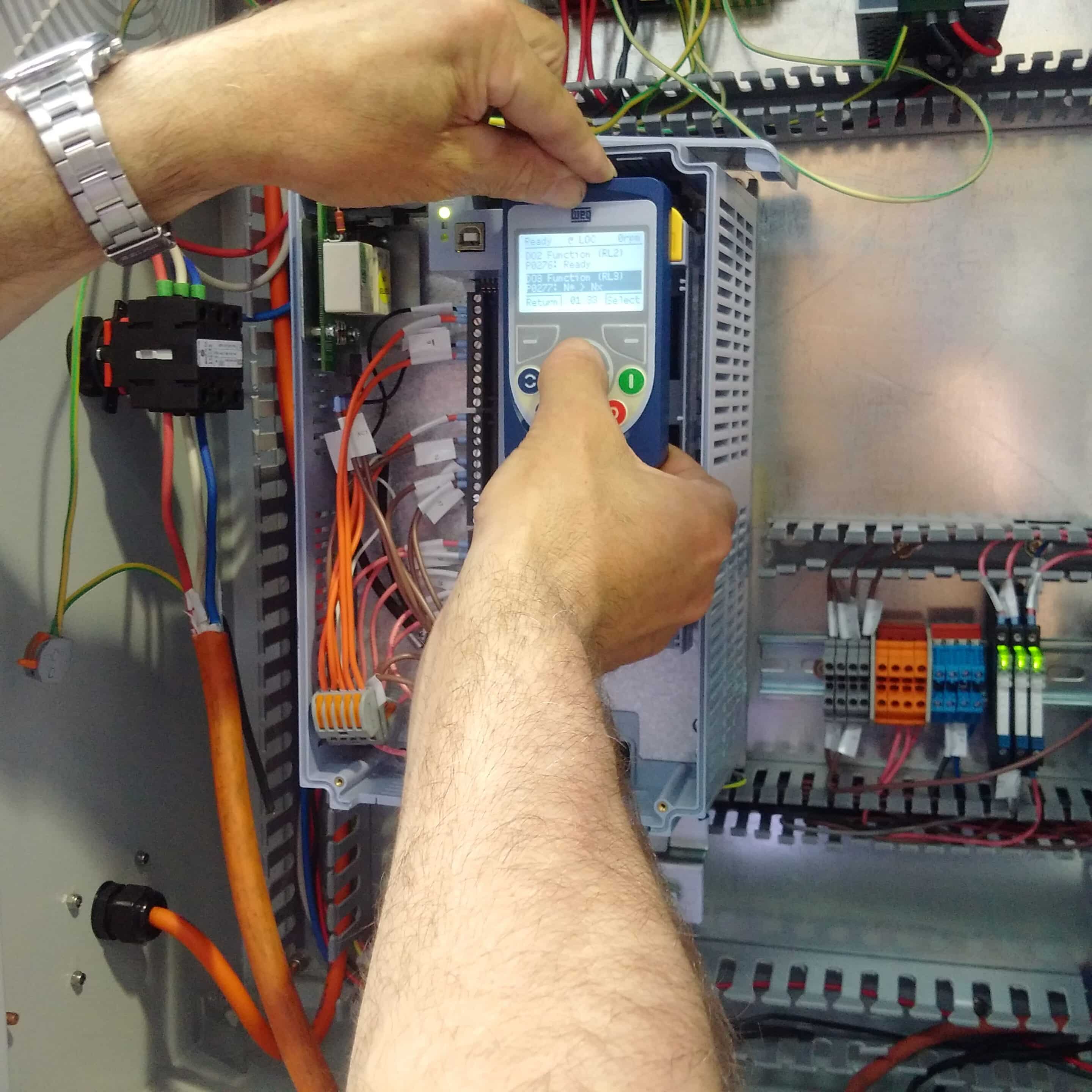

We are experienced with PLC (programmable logic controllers) programming, designing control circuits, and implementing the use of VSDs (Variable Speed Drives) in certain applications.

Euro Pumps build to the highest standing with all our Control boards are Wired to AS3000 (Australian Standards) with documented duality controls such as FAT (Factory Acceptance Test) documentation

Control Panel Design and Manufacture:

Control panels produced with components ranging from remote HMI (Human-Machine Interface) displays, VSDs, PLCs, soft starters, sub boards, etc.

Programming and Utilising Sensors:

We use a variety of sensors both programmable and non-programmable. The programmable sensors can help make decisions in your control circuit with reference to its measurements making it great for an application where a PLC isn’t being used. On the other hand, non-programmable sensors require a PLC to interpret the information being measured making them more applicable to larger scale projects.

|

|

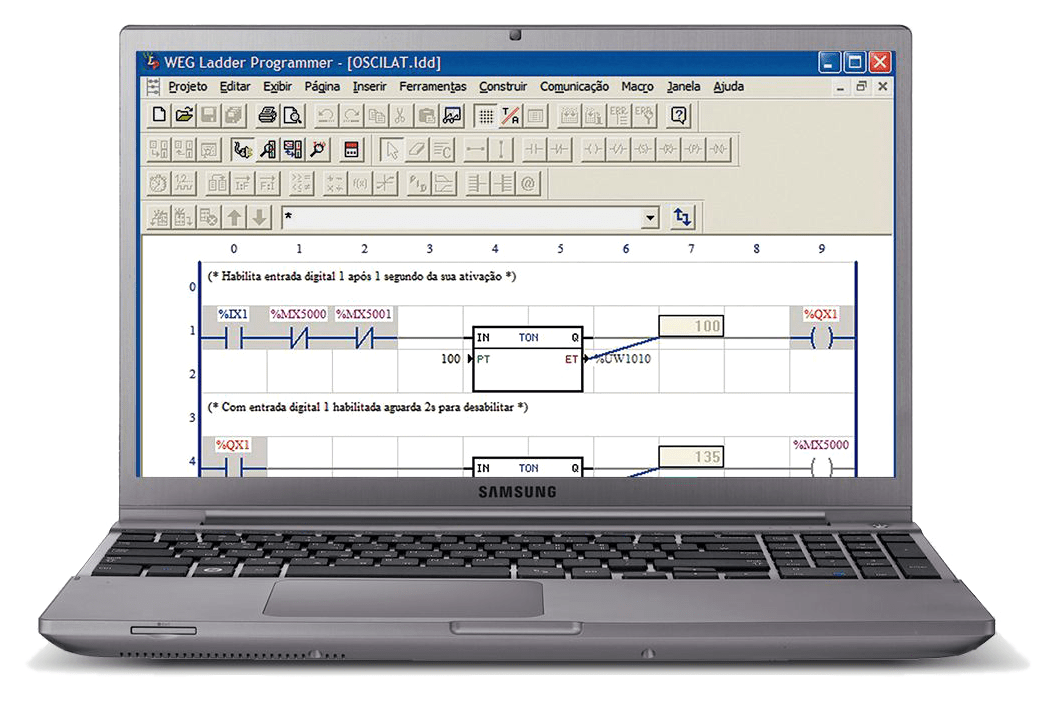

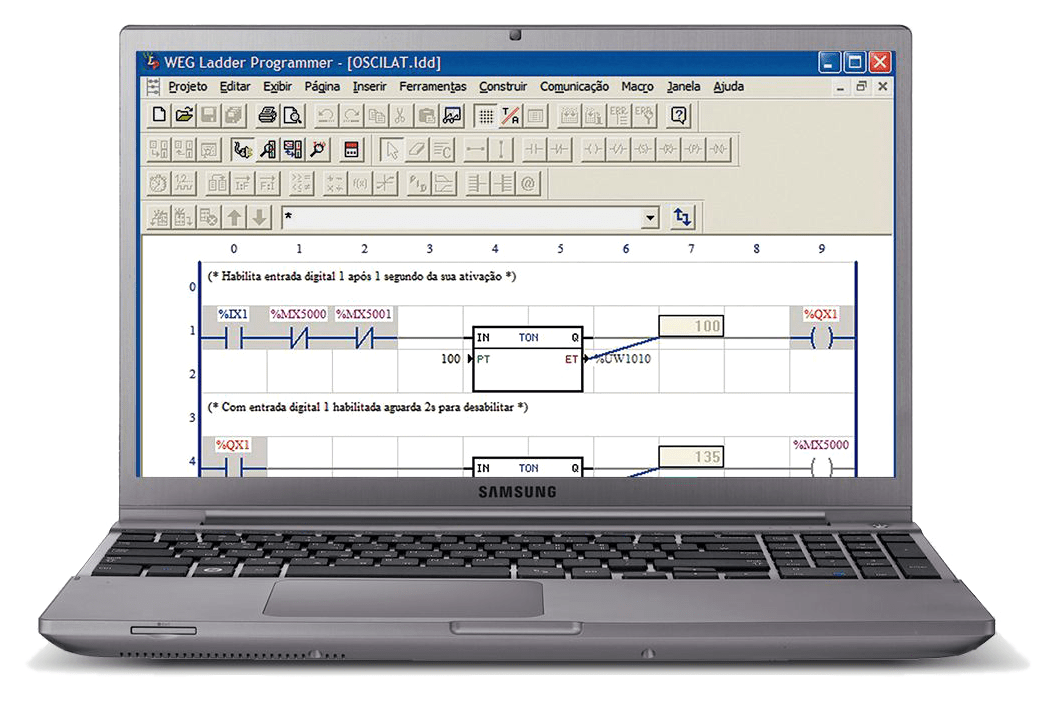

PLC Programming:

There are two brands that we utilise when programming PLCs. WEG have standalone PLCs and onboard PLCs integrated to their VSDs. This makes WEG drives extremely versatile when it comes to your need. Using ladder logic programming on WLP11 software, programming is simple and effective giving endless possibilities on top of having the option of a speed drive. On the contrary, IFM Efector only manufacturer standalone PLCs. However, these PLCs offer more inputs and outputs meaning if it is just a control circuit you are looking to design, this would most likely be the favourable option.

Written documentation:

Panel schematics and PLC code can be supplied if required. Furthermore, access to our programming software is made possible as it is free. Board layouts and electrical schematics can be provided in both CAD and PDF formats. These include information regarding operator procedures, start up, running, control panel SCADA/HMI screen explanations, lock out tag out procedures, energy isolation, etc.

Ongoing Support:

We support continuous changes and improvements made in your system.

Phone Support:

Call us any time to help troubleshoot, answer installation questions, help purchase replacement parts, or any other troubles you may encounter.

Online Support:

We can connect a LAN (or cellular) modem to your site if you would like programming modifications or troubleshooting. On top of that, we use Team Viewer which is a free program used for online access over your computer to make changes or updates to your program from anywhere in Australia. .

On-Site Travel:

We are available to help on site whenever possible or can recommend a local controls integrator to help you further with your needs.

Communication Technology:

We use technologies such as Modbus-RTU, Modbus-TCP, Profibus-DP-V1, DeviceNet, CAN, EtherNet/IP, EtherCAT, PROFINET-IO and BACnet.

Contact Us

Please enter all fields so we can get back to you