WEG motors, soft starters, and variable frequency drives

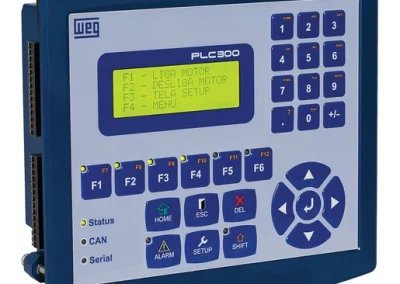

WEG Controllers

WEG Programmable Controllers replace auxiliary contactors, timers and electromechanical counters, optimizing spaces and significantly facilitating maintenance activities.

Features

- 10 digital and 1 analog built-in inputs, 9 digital (1 fast) and 1 analog built-in outputs;

- Possibility of digital and analog I/O expansion via CANOpen network;

- I/O expansion modules of the CFW11;

- Built-in encoder input (100Khz);

- Communication interface: Modbus-RTU (Master), CANOpen (Master);

- Up to 240 screens programmed by the user;

- Programmed in ladder language using the WPS free software application (Weg Programming Suite);

- Front HMI and possibility to customize the membrane (available in the version with built-in HMI – HPC and HSC models);

- Back display for the back panel version (BP and BS models);

- Built-in USB port to communicate with the computer;

- Internal flash memory;

- Battery voltage monitoring;

- Ethernet Modbus-TCP Port;

- SD card port;

- Communication with the PWS line of graphic HMIs (3.3 to 15”).

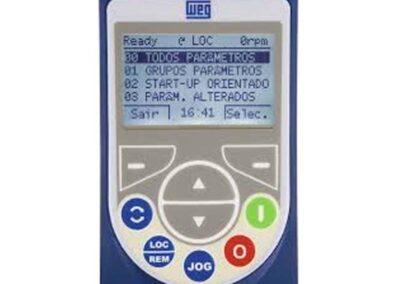

WEG VSD/PLC

WEG CFW11 Series achieves a performance increase over most complex drive systems (6 A to 365 A), with wide range of communication protocols and Plug-and-Play accessories.

Features

Power supply:

- 200 to 240 V single-phase: output current from 6 to 10 A (2.0 to 3 cv)

- 200 to 230/240 V three-phase: rated output current from 7.0 to 211 A (2.0 to 150 cv)

- 380 to 480 V three-phase: rated output current from 3.6 to 720 A (2 to 970 cv)

- 500 to 600 V three-phase: rated output current from 2.7 to 435 A (2 to 850 cv)

- 500-690 V three-phase: rated output current from 2.7 to 365 A (3 to 850 cv)

- Built-in inductors on the DC Link

- Space saving in the panel

- Built-in USB port

- Inverter smart cooling system

- Several communication protocols available (Modbus-RTU, Modbus-TCP, Profibus-DP-V1, DeviceNet, CANopen, EtherNet/IP, EtherCAT, PROFINET-IO and BACnet)

- Version with cabinet with degree of protection IP55 (versions with built-in switch-disconnector)

- High precision and reliability in speed and torque control

WEG Soft Starters

WEG Soft-Starters, offer longer lifespan of the motor and equipment. Designed for acceleration, deceleration and protection of three-phase induction motors.

Features

- Currents: 17 to 412 A

- Voltage: 220 to 575 V

- Built-in bypass

- High starting duty

- Total control on the three phases

- Protection of the motor and built-in starter

- “Kick-Start” function for starting loads with high static friction

- Remote or local HMI (optional)

- Input for the motor PTC (optional)

- Operation in environments up to 55 °C

- Extremely reduced weights and dimensions

- RS-232, RS-485, DeviceNet or Ethernet communication (optional)

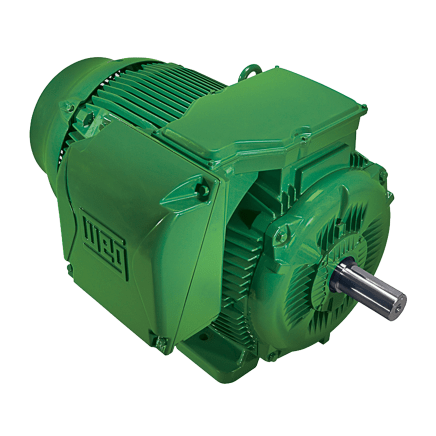

WEG W22 Motors

With cast iron frame, flexible mounting, solid/whole feet, and lower noise levels and operating temperatures, the W22 motors are perfectly suitable for a variety of industrial applications.

Cooler by design

The ventilation system design of the W22 line provides lower noise levels and allows a better distribution of the air flow over the motor, which minimizes hot spots on the surface and increases reliability and useful life.

- The fan cover made of cast iron offers greater impact resistance IEC 160 / NEMA 254T and larger and all IEEE 841 (IEC 63-132 / NEMA 143T-215T standard W22 are heavy gauge stamped Steel)

- Terminal box and eyebolts positioned so as to reduce the air flow dispersion

- Lower operating temperature on the bearings, resulting in longer lubrication intervals

Contact Us

Please enter all fields so we can get back to you